MS132 - 14 hours

COURSE OBJECTIVES

To diagnose symptoms of deterioration, plan and carry out preventive maintenance.

To understand the technology of vacuum production and cryogenic pumps.

To be able to carry out a complete level 1 maintenance on cryogenic pumps independantly.

This training will give you the knowledge and the good practice that will allow you to maximise the use, performance and lifespan of the pumps.

AUDIENCE

Maintenance staff and users.

Maintenance Technicians.

AUDIENCE

Prior experience on vacuum installations is preferable.

INNOVATIVE TEACHING RESOURCES

Lectures and «hands on» exercises.

Customised training manual.

Prior interview with the trainees possible in order to qualify their needs.

Multiple choice questions at the start and end of the training.

Training centres integrated with 40-30 workshops.

During this training, using AMPS, an interactive pedagogic tool, practical maintenance.

Maximum 6 persons per group.

PRICE per person

Please, contact us.

We need 3 registrations to open a session.

DATE & LOCATION

Training Department : +33(0)4 76 84 40 30

Can be also held in your premises for a specific training.

Each session is limited to 6 trainees.

MAIN TRAINER

Michel THIAM: PhD in Physics (Strong Experience in Surface Physics and Surface Chemistry under UHV Conditions), from 40-30 Engineering Department; certified COFREND NDT Using level 2.

|

PROGRAM

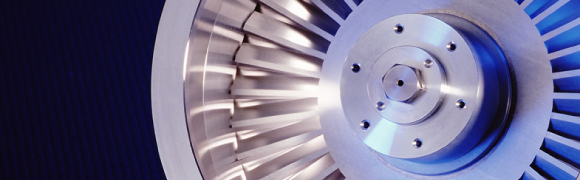

1- The physics of vacuum

General familiarisation on the production of vacuum

Notions of pressure

Choice of the pump depending of the process

2- Technology, operation and use of vacuum pumps

Overall view

Design and function

Pollution and decontamination

Measurement of vibration

Maintenance frequency

Recognition of the symptoms caused by deterioration

3- Overhauling the Cryo OB400

Decontamination

Disassembling the vacuum side of the pump

Rebuild the vacuum side

Helium leak detection

Installation of the pump on to the test bench

Testing using the dedicated bench

4- Diagnostics and fault finding

Most common breakdowns: contamination problems, leak detection…

Selection of equipment according to your application.

|