MS711 - 21 hours

TRAINING OBJECTIVES

To maximise equipment lifespan by the introduction of best practice and regular maintenance.

To plan and to carry out preventive maintenance.

To identify appropriate timing to perform minor preventative maintenance in order to avoid major equipment failure.

To practice deterioration diagnosis and to understand failure symptoms.

To overhaul pump.

AUDIENCE

Maintenance technicians

PREREQUISITES

Previous experience on vacuum installations is recommended.

INNOVATIVE TEACHING RESOURCES

40-30 will make use of AMPS® (Advanced Management Procedures System); attendees will be guided through step-by-step maintenance. In addition, sectioned rotary pumps will be used to explain how the mechanism works. We are also targeting improving your pumps ‘in service’ life by further educating your maintenance staff.

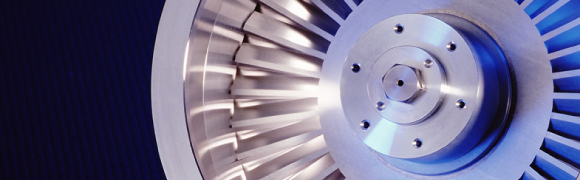

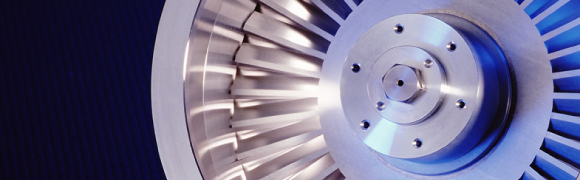

Pumps to be used or seen during the training sessions: cross-sectional views of primary roughing and high vacuum pumps.

Trainees will have the opportunities to be trained on their own equipment or on 40-30’s equipment.

DATES & LOCATION & PRICE

Training Department : +33(0)4 76 84 40 30

At your premises or in one of our training centres.

Please contact us for a quotation.

Session limited to 6 attendees.

MAIN TRAINER

Pierre-Aimé BOISSON: Maintenance Engineer, used to solve maintenance and productivity issues on vacuum pumps

|

PROGRAM

Introduction to the principles of vacuum physics

Operation and use of rotary pumps

Basic concept of vacuum pumping, pressure measurement.

Calculating the pump down time of a vacuum system

Dimensioning a vacuum system

Operating principles of a rotary vane pump,

General familiarisation on vacuum technologies.

Pumping of condensable gases, outgassing.

Maintenance of primary rotary pumps

Different types of pump oils

Partial disassembly of a primary rotary pump and assessment

Main causes of failures and remedies

Recognizing symptoms of failures

Maintenance frequency

Hands-on training

Complete maintenance on 3 types of rotary pumps: disassembly, cleaning, assessment, reassembly and replacement of the maintenance kit, testing.

Diagnosis of symptoms announcing a malfunction on a piece of equipment.

Selecting the brand and type of vacuum pumps according to your work application: ALCATEL, LEYBOLD, EDWARDS…

|