MS124 - 7 hours

TRAINING OBJECTIVES

Follow the fleet and the level 1 preventive maintenances of the chillers.

Diagnose the symptoms of deterioration, plan and realization of preventive maintenances.

Decide to replace or not the chiller, in case of failure.

Have the necessary knowledge and exercises for maximizing the maintenance of the fleet, in order to extend the lifespan of the equipment.

AUDIENCE

Maintenance technicians and users.

INNOVATIVE TEACHING RESOURCES

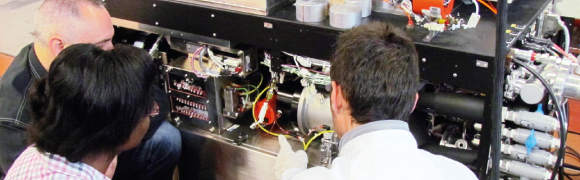

Lectures and «hands-on» exercises.

Presentation, exercises and demonstration during the training (theory: 30%; practice: 70%)

The practical work will be carried out on the most common equipment used in the semiconductor environment (Neslab HX150 / Steelhead). The program will be adapted to your profile (refrigeration specialist, mechanic, electro technician). This type of training helps to demystify the equipment

DATE & LOCATION & PRICE

Training Department : +33(0)4 76 84 40 30

Please, contact us.

In your premises or in one of our training centers.

Each session is limited to 6 trainees.

Can be also held in your premises for a specific training.

IN CHARGE OF THE TRAINING SESSION

Aurélie GRIET:chillers technician of 40-30

|

PROGRAM

1. Technology, operation and use of chillers

The most common equipment in industry

Start-up of a chiller

Connection precaution & coolant filling

Safety and operating instructions

2. First level maintenance

Monitoring plan of a chiller park

First level operational maintenance

3. Hands - on exercises

Expertise, manipulation of client’s equipment or equivalent equipment

Identification of different elements of a chiller

Practice of level 1 maintenance

Get started with chillers by yourself and real troubleshooting

4. Debate and exchange about the experiences of trainees

The duration of the training will be adjusted according to the needs of trainees and the number of equipment.

|