MS712 - 40 hours to 70 hours

Learning objectives

To provide RF principles diagnostic methods for generators, RF matches and plasma.

Introducing basic preventive and corrective maintenance procedures.

Health and safety.

Who will benefit most ?

Maintenance staff with electronic background.

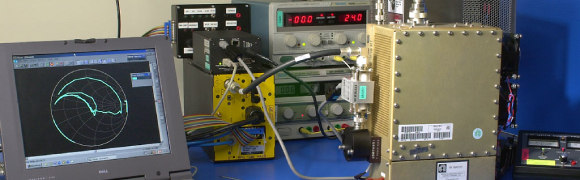

Innovative teaching resources

Training can take place at your site using your equipment. Our training has been developed to provide a high percentage of hands-on exercises in conjunction with data collection and understanding of information recorded. Training can be divided into several blocks allowing you to arrange time for production needs.

In between training blocks your staff can put into practice what they have currently learned and can share their experience during the next phase training. Our training instructor is available to audit your staff once the training has taken place. This will be used as an evaluation on skills learned to further improve your ability to become self-supportive.

Please contact 40-30 training department to discuss your training needs.

Price

Contact us for a quotation.

Dates & location

Training Department : +33(0)4 76 84 40 30

Can be held in your premises or in one of the 40-30 centers.

Sessions limited to 6 participants.

In charge of the training session

Manuel LEBE From 40-30 Engineering Department, who has developed the RF activity since 2001.

|

Program - Proposal for 5 days

1. Prerequisites

2. Complex Impedance matching

3. The RF Matchbox

4. The Skin effect

5.The RF cable

6. The RF power generator

7. The RF microwave generator

8. Metrology and methodology on testing equipment

Day 3

RFG 1250 Platform:

General presentation of the RFG platform.

RFG series block diagram review.

RFG1250 External and internal Hard Ware presentation.

Opening the unit Power Supply cavity and Boards presentation.

Opening the unit RF cavity and board presentation.

Electrical connections review.

Water connection cooling requirements and thermal stress.

RF Connections and RF Interlocks.

Interface connections / Pin assignment Review / minimum drive box.

General Interlock loop safety and how it acts in the unit.

Controlling RF level out with Set point data to the unit.

Measuring the power, on a standard dummy load.

Forward and reverse Read back analog voltages output.

Checking and showing the Reflected fold back effects when the load is not nominal.

Alarms overview, review of internal protection and survey.

Alarm leds review.

Failure review based on historic.

Reflected alarm generation.

How to measure Output RF power with Connecting Bird 4421 wattmeter and Dummy load.

How to check calibration and linearity.

How to check Reflected power protection threshold SAFETY.

Proceed to miscellaneous measurements at usual control points in the unit using a standard voltmeter and oscilloscope.

To know all the program, please contact us or download the program.

|