MS312 - 14 hours

Learning objectives

To analyze the failures linked to the RF in a methodological way, by introducing the concepts of failure rates.

The trainees will be able to elaborate a simplified scheme, extract a flowchart and find out the faulty subset.

To understand how the RF failures can influence the plasma process and the interactions of the RF generator with the other existing fluxes.

The trainee will be able to conduct a failure analysis on equipment, using RF associated metrology.

The objective of this training is to help the trainees to find solutions to RF failures on their own and improve their skills.

Who will benefit most ?

Maintenance technicians using etch and deposit equipment.

Prerequisites

A minimum level in industrial and electronics maintenance is required.

Innovative teaching resources

50% of the training time will be devoted to applied hands-on learning and analysis of situations the trainee has already faced. The training supports are constituted of Plasma coating and etching equipment (PECVD) and Plasma demonstrators. This kind of training helps shining a light on complex equipment and extracting the aspects related to RF.

The trainee will experience a real troubleshooting hands-on training on equipment.

In the preparation phase, a complete pre-audit by phone will be done with the trainee in order to identify the trainee’s needs and the duration of the training.

Price per person

1350 € ex.VAT

1150 € ex.VAT from two people registered on the same session.

Each session is limited to 4 trainees.

Dates & location

Training Department : +33(0)4 76 84 40 30

Can be also held in your premises for a specific training.

In charge of the training session

Manuel LEBE From 40-30 Engineering Department, who has developed the RF activity since 2001.

|

Program

1. Prerequisites

Review of the different parameters often used in electronics and needed to be understood for a smooth learning curve during the training.

2. Plasma

The RF energy plasma coupling and its physical parameters in order to bring the trainee an easy plasma model.

3. Complex Impedance matching and RF Matchbox

A practical approach based upon theory will shine a light on the importance and the problems linked to finding the optimum energy transfer into a plasma process, the concept of reflected power, and the associated losses.

A detailed review of the different models and design of RF matchboxes and their impact on reliability.

Energy transfer under strong RF currents and limitation due to the skin effect.

Aspect related to coupling and electromagnetic disturbance.

Elucidating the effects and the limitations due to High Frequency currents and to the type of materials.

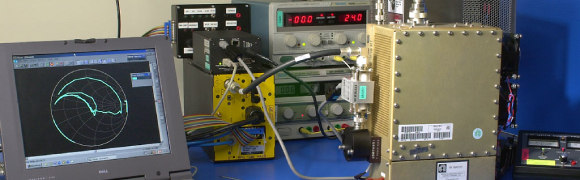

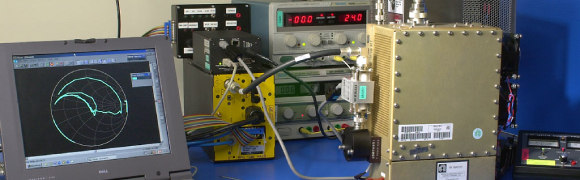

Lab work: Applied hands-on learning on Plasma coating and etching equipment (PECVD) and on Plasma demonstrators.

4. The RF cable

The RF cable seen from a practical and a theoretical perspective, its problems and its interactions with failures, choosing a RF cable and its power rating.

Lab work: Applied hands-on learning on Plasma coating and etching equipment (PECVD) and on Plasma demonstrators.

5. The RF power generator

A synthetic approach to understanding the power generator and typical associated schematics.

The interactions of the power generator with PECVD device environment.

An analysis of the most frequent failures and disturbances induced on the RF network and the Plasma.

Using RF dedicated metrology equipment for the RF generator diagnostics.

Lab work: Applied hands-on learning on Plasma coating and etching equipment (PECVD) and on Plasma demonstrators.

6. RF generator

Detailed analysis of the components of an RF generator.

Fault analysis.

Specification analysis.

7. RF microwave generator

Cavity magnetron preventive maintenance.

8. Metrology and diagnosis

This module describes the implementation of RF measuring equipment in the context of etching and deposition equipments. Fault diagrams are analyzed.

|